NANUK 908 Waterproof Ammo Case - Black

Overview

Exterior Size (LxWxH)

318 mm x 249 mm x 203 mm

Interior Size (LxWxH)

241 mm x 190 mm x 190 mm

Volume

The Quality, Fit and Finish of my new NANUK 908 are exactly what I expected, since I enjoy and being seen as a discriminating shooter, with my other NANUKS; my 908, Ammo Case; 935, 6-up Handgun case, and; my 985 Rifle Case.

My research took me to Nanuk and instantly knew I had found what I was looking for. During the time of this review I have yet to actually take it kayaking yet so I can't speak on it's performance for what I intended. However, that being said, it is a beautifully and thoughtfully designed product, as is their entire collection.

The sometimes rough and dirty environments I am in can wreck sensitive equipment. Nanuk was decently priced and had good reviews. Never heard if them beforehand, but I am very pleased with my purchase!

I love my boxes they are what I was looking for, maybe even a bit overkill as I did not buy them for shock and waterproofing. I needed them for some jigs for my business, they will enjoy laying in all that foam.

Description

NANUK 908 Waterproof Ammo Case

Overview

A clear upgrade to metal and cheap plastic cases, the NANUK 908 Ammo Case is the real thing for guaranteed dry storage.

Built to survive the harshest elements, the NANUK 908 Ammo Case is the ultimate waterproof, dustproof and rust-proof way to protect and transport your ammunition.

Don’t trust your ammo to a can that will rust or a case that is just “splash-proof”.

Count on NANUK’s two PowerClaw latches that clamp the lid shut while the high-performance rubber gasket resists deformation and fatigue to maintain a watertight seal. In fact, the NANUK 908 Waterproof Ammo Case can be submerged in 1 meter/3 feet of water for 30 minutes!

Includes two reinforced metal eyelets for padlocks or combination locks to secure the case and its contents when required.

NANUK’s pressure relief system lets air in but prevents water from entering. The 908 is designed with feet on the bottom and interlocking channels on the lid for easy, efficient and rigid stacking when transporting or storing your ammo.

NANUK cases are trusted by passionate outdoor enthusiasts, sportsmen, law enforcement, military, hunters and shooting sports enthusiasts to protect their mission-critical gear and supplies. They know that NANUK protects like no other case thanks to its lightweight, indestructible MIL-Spec NK-7 resin body. Backed by a lifetime warranty.

Holds: Approximately 600 .223 rounds (bulk)

Specifications

NANUK 908 Waterproof Ammo Case

Specifications

12.5 in x

9.8 in x

8 in

318 mm x

249 mm x

203 mm

9.5 in x

7.5 in x

7.5 in

241 mm x

190 mm x

190 mm

8.8 L

3.6 lb | 1.36 kg

1.4 in | 35 mm

6.1 in | 155 mm

Min -20°F (-29°C ) | Max 140°F (60°C)

18 lb | 8.2 kg

0.34 in | 8.6 mm

Lightweight NK-7 resin

Yes

Certifications

Downloads

NANUK 908 Waterproof Ammo Case

Downloads

NANUK 908 Waterproof Ammo Case

Overview

A clear upgrade to metal and cheap plastic cases, the NANUK 908 Ammo Case is the real thing for guaranteed dry storage.

Built to survive the harshest elements, the NANUK 908 Ammo Case is the ultimate waterproof, dustproof and rust-proof way to protect and transport your ammunition.

Don’t trust your ammo to a can that will rust or a case that is just “splash-proof”.

Count on NANUK’s two PowerClaw latches that clamp the lid shut while the high-performance rubber gasket resists deformation and fatigue to maintain a watertight seal. In fact, the NANUK 908 Waterproof Ammo Case can be submerged in 1 meter/3 feet of water for 30 minutes!

Includes two reinforced metal eyelets for padlocks or combination locks to secure the case and its contents when required.

NANUK’s pressure relief system lets air in but prevents water from entering. The 908 is designed with feet on the bottom and interlocking channels on the lid for easy, efficient and rigid stacking when transporting or storing your ammo.

NANUK cases are trusted by passionate outdoor enthusiasts, sportsmen, law enforcement, military, hunters and shooting sports enthusiasts to protect their mission-critical gear and supplies. They know that NANUK protects like no other case thanks to its lightweight, indestructible MIL-Spec NK-7 resin body. Backed by a lifetime warranty.

Holds: Approximately 600 .223 rounds (bulk)

NANUK 908 Waterproof Ammo Case

Specifications

12.5 in x

9.8 in x

8 in

318 mm x

249 mm x

203 mm

9.5 in x

7.5 in x

7.5 in

241 mm x

190 mm x

190 mm

8.8 L

3.6 lb | 1.36 kg

1.4 in | 35 mm

6.1 in | 155 mm

Min -20°F (-29°C ) | Max 140°F (60°C)

18 lb | 8.2 kg

0.34 in | 8.6 mm

Lightweight NK-7 resin

Yes

NANUK 908 Waterproof Ammo Case

Downloads

Why Choose The NANUK 908 Waterproof Ammo Case?

Keep your case from sealing shut. Automatically.

Automatic Pressure Release Valve

Stand out with a unique design and color selection.

Design & Colors

High-Impact Protection. A fraction of the weight.

Indestructible & Lightweight NK-7 Resin

Go where no case has gone before.

IP67 Waterproof & Dustproof

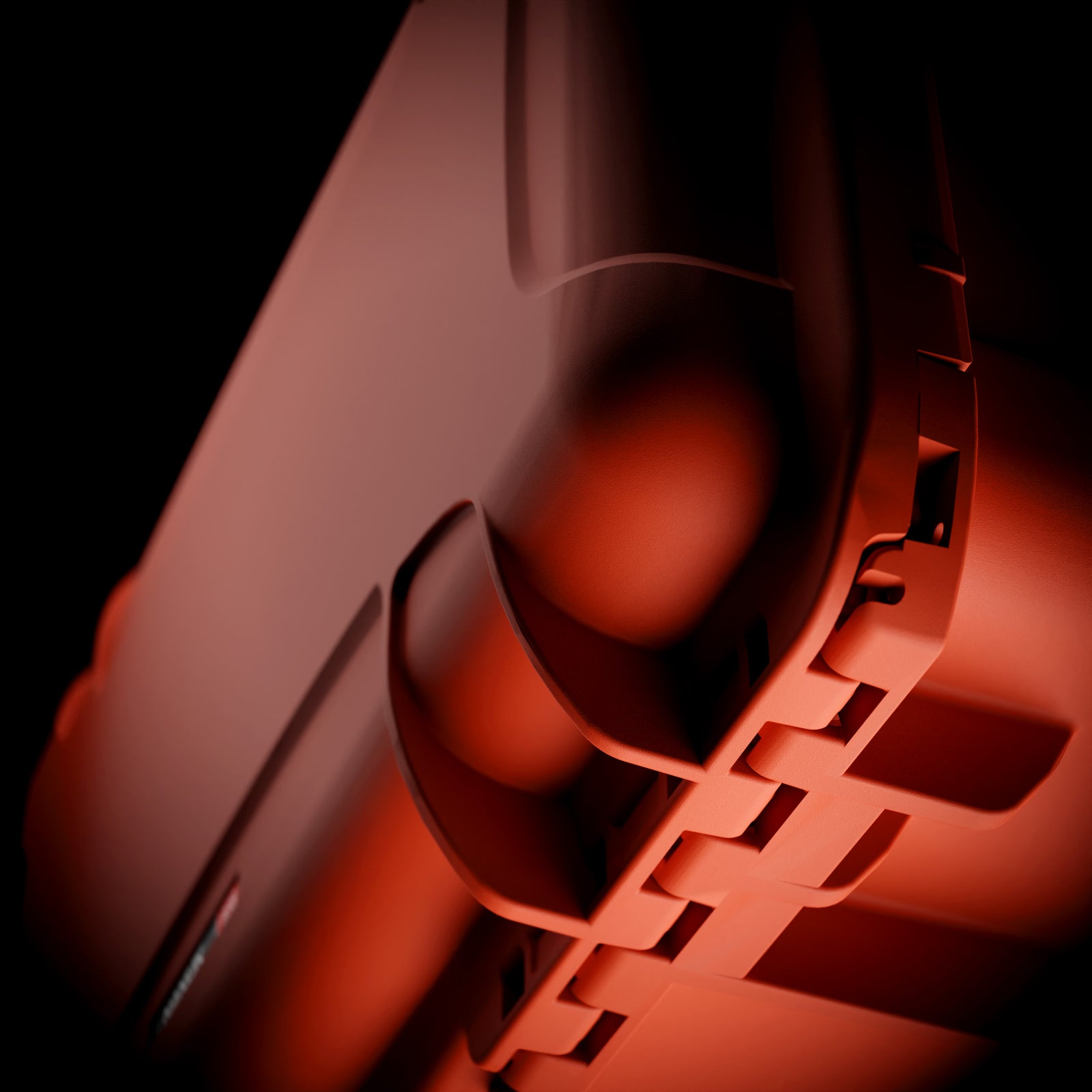

Close with confidence. Open with ease.

PowerClaw Superior Latching System

Customer Reviews